The Visuddhimagga, a fifth-century Indian text, poses a riddle: “Precisely where is what we call a ‘chariot’ located? Is it in the axles, the wheels, the frame? Is it in the poles that connect to the horse?”

The answer: Nowhere. What we mean by the term “chariot” refers to the temporary arrangement of its component parts. It’s an illusion.

The ancient text uses that insight to illustrate the elusive nature of the self, which resides neither in our memories nor in our thoughts, perceptions, sensations, or actions (an analysis that anticipated modern philosophy’s deconstruction of the self by 1,500 years). But this insight applies as well to a Game Boy, a blender, or any manufactured thing. Every such object breaks down into the multitude of its parts and the constituent processes that made them.

An industrial engineer’s version of the deconstruction of stuff is called Life Cycle Analysis, or LCA, a method that allows us to systematically tear apart any manufactured item into its components and their subsidiary industrial processes, and measure with near-surgical precision their impacts on nature from the beginning of their production through their final disposal.

LCAs had a prosaic start; one of the very first such studies was commissioned by Coca-Cola back in the 1960s to determine the relative merits of plastic and glass bottles and quantify the benefits of recycling. The method slowly spread to other industrial questions; by now a large and growing band of companies with national or international brands deploys the method somewhere along the way to make choices in product design or manufacturing—and many governments use LCAs to regulate those industries.

Life Cycle Assessment was created by a loose confederation of physicists and chemical and industrial engineers documenting the minutiae of manufacturing— what materials are used, and how much energy; what kinds of pollution are generated and toxins exuded, and in what amounts—at each basic unit in a very long chain. In the Visuddhimagga, the Riddle of the Chariot names a handful of components. Today the LCA for a Mini Cooper breaks down into thousands of components— like the electronic modules that regulate electrical systems. These electronic modules deconstruct— like the chariot into its main parts—into printed wiring board, various cables, plastics, and metals; the chain leading to each of these in turn leads to a trail of extraction, manufacture, transport, and so on. These modules run dashboard systems, regulate the radiator fan, wipers, lights, and ignition, and manage the engine—and for each of these parts in turn the analysis can run into a thousand or more discrete industrial processes. In total, that petite car’s LCA entails hundreds of thousands of distinct units.

My guide in this terrain is Gregory Norris, an industrial ecologist at the Harvard School of Public Health. With degrees in mechanical engineering from MIT and aerospace engineering from Purdue, and several years in the air force as an astronautical engineer helping build better space structures, Norris has impeccable credentials. But he readily concedes, “For LCA you don’t need to be a rocket scientist—I know, I was one. It’s mainly data tracking.”

That meticulous analysis yields metrics for harmful impacts over an auto’s life cycle, from manufacture to junked car, for the raw materials consumed; energy and water depleted; photochemical ozone created; contribution to global warming; air and water toxicity; and production of hazardous wastes—to name but a few. An LCA reveals that in terms of global warming effluents, for example, everything in the car’s life cycle from manufacture to getting scrapped pales when compared to the emissions while it is driven.

Another apt metaphor for the nature of industrial processes comes from an eighth-century Chinese treatise that describes a supernatural net belonging to the god Indra. In the heaven where Indra dwells, the text tells us, a miraculous net stretches in every direction. In each eye of the webbing glitters a magnificent jewel, cut so cleverly that its facets reflect all the other jewels in that net, in an endless web of interconnection. Any single jewel in that web bears a reflection of every other.

Indra’s net offers a handy image for the endless interconnections within and between systems in nature, as well as in man-made systems like the supply chain. When Norris walked me through a Life Cycle Assessment for glass packaging, like that for jams or pasta sauce, we ended up in a maze of interdependent linkages in a seemingly endless chain of material, transportation, and energy demands. Manufacturing bottles for jams (or anything in a glass container, for that matter) requires getting stuff from dozens of suppliers— including silica sand, caustic soda, limestone, and a variety of inorganic chemicals—as well as the services of suppliers of fuels like natural gas and electricity. Each one of the suppliers makes purchases from or otherwise utilizes dozens of its own suppliers.

The basics for making glass have changed little since the time of ancient Rome. Today, natural gas-powered furnaces burn up to 2,000 degrees Fahrenheit for 24 hours to melt sand into glass for windows, containers, or the monitor on your cell phone. But there’s far more to it than that. A chart showing the 13 most important processes deployed to make glass jars revealed a system stitching together 1,959 distinct “unit processes.” Each unit process along the chain itself represents an aggregate of innumerable subsidiary processes, themselves the outcome of hundreds of others, in what can appear an infinite regression. There are around one hundred substances released into water and fifty or so into soil along the way. Among the 220 different kinds of emissions into the air, for instance, caustic soda at a glass factory accounts for 3 percent of the jar’s potential harm to health and 6 percent of its danger to ecosystems.

Another ecosystem threat, accounting for 16 percent of glassmaking’s negative impact, results from the energy for the furnace. Twenty percent of the negatives specifically for climate change are attributed to the generation of electricity for the factory that makes the glass.

Does this mean we should stop using glass jars for foods? Of course not. Glass, unlike some plastics, does not leach questionable chemicals into fluids and remains endlessly recyclable. But as Norris took me through the highlights of that glass jar’s LCA, it hit me: all this was for a glass jar that is 60 percent recycled.

Exactly what, I asked Norris, is gained by that 60 percent? For one, he answered, the amount of new glass replaced by the recycled content saves about that proportion of weight in raw materials extracted, processed, and transported. “Of course you still need to process and transport post-consumer glass, but the net impact of glass recycling is still beneficial,” he reassured me, adding an example: “Every 28 percent of recycled content saves 500 gallons of water per ton of glass produced, and avoids emissions of 20 pounds of CO2 to the atmosphere.”

And yet all those other impacts remain, despite the recycling. This transforms our notions of “green” from what seems a binary judgment—green or not—into a far more sophisticated arena of fine distinctions, each showing relatively better or worse impacts along myriad dimensions. Never before have we had the methodology at hand to track, organize, and display the complex interrelationships among all the steps from extraction and manufacture of goods through their use, to their disposal—and summarize how each step matters for ecosystems, whether in the environment or in our body.

In this light, consider the tote bags British fashion designer Anya Hindmarch put out in a limited edition of 20,000. Hindmarch’s inspiration came when she was approached by a charity called We Are What We Do. She decided to use her fashion platform to raise public awareness about refusing plastic bags in stores. And that it did.

Priced at $15, the bags were sold in supermarkets rather than the pricey boutiques where Hindmarch’s handbags are usually to be found. Eager buyers lined up at the selected stores throughout England as early as 2 a.m.—and by 9 a.m. not one remained. When they later went on sale at Whole Foods’ flagship market on Columbus Circle in Manhattan, the bags were snapped up within thirty minutes. When the bags were made available in Hong Kong and Taiwan, shoppers were injured in stampedes—so the bag’s release in Beijing and several other cities was canceled. And in Britain the bags were repeatedly mentioned in nationwide discussions about higher standards for recycling.

Hindmarch’s eco-chic suggests one way smart habits and products can nudge us to change our ways. And change we must. Those little plastic bags we carry our purchases home in are an ecological disaster. In the United States alone 88 billion are used each year; their abundant cousins are blowing in the breeze from São Paulo to New Delhi caught in shrubbery, filling gutters, and killing animals that eat or get caught in them. The biggest curse: they take an estimated five hundred to one thousand years to decompose.

Not that paper bags are necessarily better. The EPA estimates that it takes more energy and pollutes more water to make paper bags than plastic ones. There are pros and cons on both side of the paper-versus-plastic debate. Plastic bags, for instance, are 100 percent recyclable— though in the United States only about one in a hundred actually gets recycled.

Still, the smart answer to “Paper or plastic?” is “Neither—I brought my own bag.” This is already standard practice throughout many parts of the world, where customers have to pay stores for shopping bags or bring their own; the practice has been spreading through stores in the United States. But LCA raises the question, what are the impacts of that virtuous bag?

Hindmarch’s company went to great lengths to make her bags ecologically correct: they were manufactured in factories certified to offer fair wages with no child labor, carbon offsets were purchased to cover the impacts of manufacture and transport, and they were sold at cost. Hindmarch even tried to use fair trade cotton, bought directly from small growers, but could not find enough, and so settled for organically grown.

And yet you have to wonder what an LCA of that exemplary bag might reveal about all the ways it harms the environment—and thus all the ways it could become even more virtuous.

THAT HINDMARCH CANVAS tote was emblazoned with the slogan “I’m NOT A Plastic bag,” a play on the 1929 painting by the Belgian surrealist René Magritte depicting a pipe, below which were the words Ceci n’est pas une pipe—“This is not a pipe.” The painting’s title, The Treachery of Images, underscores Magritte’s point that the image is not the thing and things are not what they seem.

The other day I bought a T-shirt that hung in a prominent spot in a department store. My T-shirt bears the proud label “100% Organic Cotton: It Makes a World of Difference.”

That claim is both right and wrong.

First, what’s right: the benefits of forgoing pesticides in cotton. Cotton crops alone account for about 10 percent of the world’s use of pesticides. To prepare soil so that fragile young cotton plants can grow, workers spray the soil with organophosphates (linked to central nervous system damage in humans), which kill off any plant that might compete with the cotton or any insect that might eat it.

Once soil has been so treated, it can take up to five pesticide-free years before even earthworms return, a vital step in recovering soil health. Then there’s the paraquat sprayed by crop dusters on cotton just before it’s harvested. About half this defoliant typically misses the cotton and ends up in streams and fields nearby. Given the damage done by pesticides, there’s little question about the intrinsic environmental goodness of organic cotton—so far as it goes.

Then there are the downsides. For example, cotton has a prodigious thirst. It takes about 2,700 liters of water to grow the cotton for one T-shirt; the Aral Sea evaporated into desert largely because of the irrigation demands of regional cotton farms. Simply tilling the soil has its own ecosystem impact, releasing carbon dioxide.

The organic T-shirt I bought was dyed a dark blue. Cotton yarn gets bleached, dyed, and finished with industrial chemicals that include chromium, chlorine, and formaldehyde, each toxic in its own way. What’s worse, cotton resists absorbing dye, and a large amount rinses off into factory wastewater, which can end up in local rivers or groundwater. Some commonly used textile dyes harbor carcinogens—epidemiologists have long known that workers in dye plants have unusually high rates of leukemia.

That label on my T-shirt exemplifies “greenwashing,” the selective display of one or two virtuous attributes of a product meant to impart goodness to the whole thing. The more complete analysis of its hidden impacts reveals multiple ways in which the T-shirt may not be so green after all. Although an organic shirt is all to the good, when the adverse impacts of a product stay hidden, the “organic” part at best marks the first step toward a business becoming more socially responsible or sustainable; at worst, it is a marketing ploy.

Greenwashing creates merely the illusion we are buying something virtuous.

When the fast-food chain Dunkin’ Donuts announced that its doughnuts, croissants, muffins, and cookies would henceforth be “trans fat free,” the company joined most other major players in its industry in making its foods a bit healthier. But the operative phrase is a bit: all those “zero trans fat” pastries remain an unhealthy mix of fat, sugar, and white flour. When nutritionists analyzed ingredients in tens of thousands of supermarket items, they found—no surprise—that a vast number of foods marketed as “healthy” choices were not.

From a marketing perspective, spotlighting the organic cotton in a T-shirt or the absence of trans fats in a doughnut imbues that product with the sheen of virtue. Advertisers, of course, tout one or two positive qualities of a product to shine up its market appeal. Playing up the sizzle, not the steak, has always been standard operating procedure.

But that attentional bait and switch directs shoppers’ focus away from whatever negatives a given product may still have. The T-shirt’s dyes are as dangerous as ever, just as a “zero trans fats” doughnut still harbors fats and sugars that drive insulin levels sky high. But so long as we stay focused on that thin slice of virtue in the T-shirt or the doughnut, we can buy it feeling good enough about our choice.

So greenwashing merely creates the illusion that we are buying something virtuous. Such products are greenish—they are draped with the mere appearance of ecological merit.

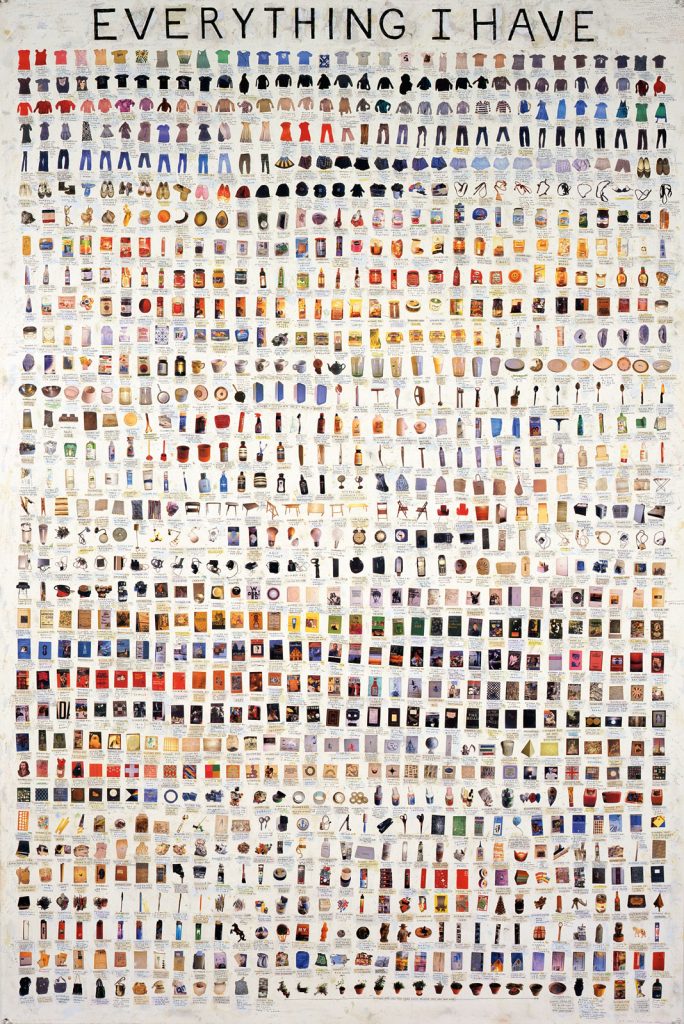

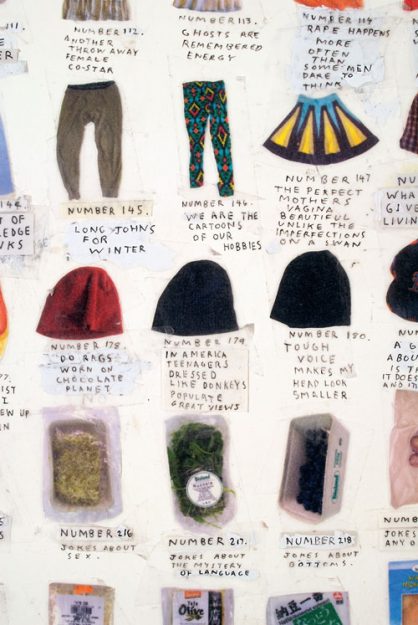

![Everything I Have [detail]](https://tricycle.org/wp-content/uploads/2015/12/064eih.jpg)

Every small step toward green helps, to be sure. But our craze for all things green represents a transitional stage, a dawning of awareness of ecological impact but one that lacks precision, depth of understanding, and clarity. Much of what’s touted as “green” in reality represents fantasy or simple hype. We are past the day when one or two virtuous qualities of a product qualify it as green. To tout a product as green on the basis of a single attribute—while ignoring numerous negative impacts—parallels a magician’s sleight of hand.

That quasi-green T-shirt is not alone; consider a study of 1,753 environmental claims made for over a thousand different products plucked from the aisles of big-box stores. Some paper brands, for instance, focus on a narrow set of features, like having some recycled fiber content or chlorine-free bleaching, while ignoring other significant environmental issues for paper mills, such as whether the pulp comes from sustainable forestry, or whether the massive amounts of water used are properly cleansed before return to a river. Or there’s the office printer that proclaims its energy efficiency but ignores its impact on the quality of indoor air, or its incompatibility with recycled printer cartridges or recycled paper. In other words, it was not designed to be green from cradle to grave, but only engineered to tackle a single problem.

To be sure, there are relatively virtuous products, building materials, and energy sources. We can buy detergent without phosphates, install carpet that exudes fewer toxins or flooring of sustainable bamboo, or sign up for energy that comes mainly from wind, solar, or other renewable sources. And all that can make us feel we have made a virtuous decision.

Our current fixation on a single dimension of “green” ignores the multitude of adverse impacts that shadow even the most seemingly virtuous of items.

But those green choices, helpful as they are, too often lull us to more readily ignore the fact that what we now think of as “green” is a bare beginning, a narrow slice of goodness among the myriad unfortunate impacts of all manufactured objects. Today’s standards for greenness will be seen tomorrow as eco-myopia.

“Very few green products have been systematically assessed for how much good they actually do,” says Gregory Norris. “First you have to do an LCA, and that’s rare.” Maybe thousands of products of any kind have gone through these rigorous impact evaluations, he adds, “but that’s a tiny fraction—millions are sold. Plus, consumers don’t realize how interconnected industrial processes are,” let alone their myriad consequences.

“The bar is too low for green products,” Norris concludes. Our current fixation on a single dimension of “green” ignores the multitude of adverse impacts that shadow even the most seemingly virtuous of items. As Life Cycle Assessment of just about anything shows, virtually everything manufactured is linked to at least trace quantities of environmental toxins of one kind or another, somewhere back in the vast recesses of the industrial supply chain. Everything made has innumerable consequences; to focus on one problem in isolation leaves all the other consequences unchanged.

A publisher (not mine) wanted to make a book as “green” as possible. He found paper that had been whitened by an eco-friendly oxygenation method rather than with tons of chlorine, and he bought energy offsets—investments like wind farms on Native American reservations—to compensate for the energy used to produce the book. But there were obstacles. “One big problem was with the ink,” he told me. “Ink used to print books has been made from synthetic chemicals that are toxic. When a print run for a book finishes, the printers needed to wash their rollers; they used to just wash the ink off their rollers into water runoff from their plants. Now they try to capture the excess ink. If the ink is water based, then they can do this—but if oil based, they need to wash their rollers with a solvent, many of which are also toxic. Soy-based ink has become fashionable as a green alternative, but ‘soy’ ink in fact has just 8 to 10 percent soy; the rest is just as bad as ever. I tried to use soy ink, but I need a four-color ink process for the graphics, and only three of the inks met the standard for soy—the fourth was a bit short of the 8 percent requirement. So I couldn’t make that claim.”

Indeed, nothing made industrially can be utterly green, only relatively more so; Indra’s net reminds us that every manufacturing process has adverse impacts on natural systems somewhere along the way. As one industrial ecologist confided, “The term ‘eco-friendly’ should not ever be used. Anything manufactured is only relatively so.”

This shadow side of industry has been overlooked in the value-chain concept, which gauges how each step in a product’s life, from extracting materials and manufacture through distribution, adds to its worth. But the notion of a value chain misses a crucial part of the equation: while it tracks the value added at each step of the way, it ignores the value subtracted by negative impacts. Seen through the lens of a product’s Life Cycle Assessment, that same chain tracks a product’s ecological negatives, quantifying its environmental and public health downsides at each link. This window on a company or product’s negative ecological footprint might be called the “devalue chain.”

Such information has strategic importance. Every negative value in an LCA offers a potential for upgrading, and so mitigating the item’s overall ecological impacts. Assessing the pluses and minuses throughout a product’s value chain offers a metric for business decisions that will boost the pluses and lessen the minuses.

In a day when major players in every industry, and more and more consumers, are pressing for green, we would do well to understand the implication of improving impacts all along the supply chain and throughout a product’s life cycle. Green is a process, not a status—we need to think of “green” as a verb, not an adjective. That semantic shift might help us focus better on greening.

Thank you for subscribing to Tricycle! As a nonprofit, we depend on readers like you to keep Buddhist teachings and practices widely available.